M Sand: The Sustainable Alternative to River Sand

Owing to rapid urbanization and large-scale construction activities, the demand for sand has skyrocketed. However, sand scarcity is a problem affecting many countries, including India. With natural sand, which is found in riverbeds and coastal regions, becoming inadequate to meet the huge demand and the environmental impact caused due to sand extraction from natural sources, M sand or manufactured sand has emerged as a sustainable option.

The Shift to M Sand in India

The construction sector in India is now relying on manufactured sand instead of river sand. Many real estate developers across major cities like Delhi, Mumbai, Chennai, Bangalore, and Pune have shifted to using M sand, as it is affordable and eco-friendly.

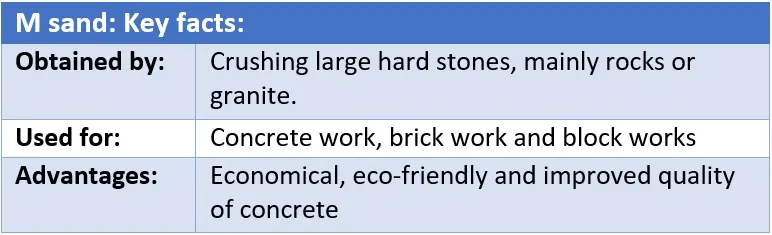

What is M Sand?

M Sand Meaning

M sand is a form of artificial sand, manufactured by crushing large hard stones, mainly rocks or granite, into fine particles, which are then washed and finely graded. It is widely used as a substitute for river sand for construction purposes, mostly in the production of concrete and mortar mix. Manufactured sand or M sand is also referred to by other names such as crushed sand, crushed stone sand, artificial sand, pozzolan sand, etc.

M Sand Price in India

The cost of manufactured sand in a city like Bangalore is mentioned below:

| Cost | M Sand | River Sand |

|---|---|---|

| Market price | Rs 600 to Rs 700 per metric ton | Rs 1,200 per metric ton (approximately) |

| In concrete | Rs 500 per cubic metre (approximately) | Rs 900 per cubic metre (approximately) |

| In mortar (1:5) for 100 kgs | Rs 160 (approximately) | Rs 200 (approximately) |

M Sand: Manufacturing Process

The manufacturing process for M sand takes place in three stages:

- Crushing: Stones of varying sizes are crushed into aggregates using vertical shaft impact (VSI) crushers.

- Rotopactor: The material is then fed into a Rotopactor for crushing the aggregates into sand to the desired grain size.

- Screening and Washing: The process of screening removes dust particles, and washing eliminates minute particles.

M Sand vs River Sand Properties

M sand differs significantly in physical and mineralogical properties compared to river sand. Here are the main properties of manufactured sand:

- Shape: Cube-like or angular.

- Texture: Rough, preferred for making concrete.

- Water Absorption: 2% to 4%.

- Particle Size: No oversized particles.

- Impurities: Lesser impurities compared to river sand.

- Bulk Density: 1.75 gm per cubic cm.

- Specific Gravity: 2.5 to 2.9, depending on the parent rock.

- Fines: Permissible limit of fines below 75 microns is up to 15%.

- Gradation: Controlled gradation of Zone-II, ideal for concrete.

Advantages of M Sand

High Strength of Concrete

Manufactured sand possesses the desired properties like shape, smooth texture, and consistency, and required gradation of fines. These qualities lend greater strength to the concrete structure.

Improved Quality of Concrete

Due to low impurities such as clay, dust, etc., the sand helps produce better quality concrete. Moreover, the use of manufactured sand reduces construction defects in concrete, such as segregation, bleeding, honeycombing, voids, and capillarity.

Durability of Concrete

Since the sand is produced using a selected quality of granite, it possesses the right physical and chemical properties for making concrete structures. Due to its unique properties, manufactured sand enables structures to withstand extreme weather conditions and prevents corrosion of reinforcement steel.

Better Workability of Concrete

Manufactured sand requires a lower water-to-cement ratio, thus, providing workable concrete. It improves the consistency of the concrete, increases the strength, and requires less effort for mixing and placement of concrete, therefore, improving productivity.

Economical

Since there are no impurities, there is no wastage. Moreover, the cost of transportation of M sand is 30% to 50% lower than the transportation cost required for river sand.

Eco-friendly

The use of manufactured sand eliminates the need for dredging of riverbeds for extracting river sand, which can have an adverse environmental impact, such as water depletion threat and impact on the safety of dams and bridges.

Other Advantages of M Sand

- Around 30% increase in masonry strength is achieved using manufactured sand.

- M sand achieves a better bond with cement than the round particles of natural sand due to its sharp-edged particles.

- Some studies prove that concrete made using M sand has 6% to 9% higher compressive strength and 12% to 15% higher flexural strength than river sand material of the same grade.

- M sand has good abrasion resistance.

Disadvantages of M Sand

- The angular texture or flaky particles obtained from improper crushing may lead to increased water and cement requirements, thus making it unsuitable for concrete production.

- Non-availability of adequate setup for crushers in some parts of the country, such as West Bengal, can be a problem, owing to the higher costs as compared to river sand.

- The requirement of cement is higher as compared to river sand for high-grade pumpable concrete in high-rise structures, which may not be economical.

Types of M Sand

Manufactured sand is classified into the following types:

M Sand for Concreting

This type of M sand is used in concrete. The granule thickness or the sieve size is 150 microns – 4.75 mm. It conforms to IS Code 383:1970.

M Sand for Plastering

This type of sand finds application in tiling and wall plastering purposes. The granule thickness or sieve size is 150 microns – 2.36 mm. It conforms to IS Code 1542: 1992.

M Sand for Brick or Block Work

This type of sand is mainly used for masonry or brick or block-laying works. The granule thickness or sieve size is 150 microns – 3.55 mm. It conforms to IS Code 2116: 1980.

Difference Between M Sand and River Sand

| Factors | M Sand | River Sand |

|---|---|---|

| Definition | M sand is produced by crushing large aggregate pieces, rocks, or quarry stones in a quarry or factory | River sand is a type of sand that is naturally available and extracted from riverbanks or riverbeds |

| Shape | Angular or cubical | Rounded |

| Texture | Rough | Smooth |

| Moisture Content | Less or no moisture content | Presence of moisture |

| Presence of Marine Products | No | 1% to 2% of seashells, tree barks, etc. |

| Dry Density | 1.75 kg per cubic m | 1.44 kg per cubic m |

| Particle Passing 75 Micron | Up to 15% (IS: 383 – 1970) | Up to 3% (IS: 383 – 1970) |

| Specific Gravity | 2.73, depending on the parent rock | 2.65, depending on the rocks in the catchment area |

| Adulteration | Less impurities | High impurities |

| Applications | Highly recommended for RCC work, brick work, and block works | Suitable for RCC work, brick work, and block works |

| Environmental Impact | Eco-friendly as compared to natural sand | The use of river sand can reduce groundwater levels and lead to the drying up of river water |

M Sand Latest Updates

The Tamil Nadu government is planning to draft a new policy for manufacturing artificial sand and regulate its sales. In January 2021, the state’s Public Works Department submitted the final draft of the M-sand policy to the government. The objective of the proposed policy would be to promote the use of manufactured sand as an alternative construction material. Once the policy comes into effect, it will be mandatory for manufacturers to obtain approvals for the quality of material being used. It will also help in the regulation of the trade and keep a check on adulteration and violations of norms.

Difference Between M Sand and P Sand

P sand, which refers to Plastering Manufactured Sand, is crushed sand or manufactured fine aggregate, primarily used for plastering and creating renders. It helps provide a smooth finish to the plasters. P sand is considered better than M sand and finds many applications. On the other hand, M sand is utilized for concrete or mortar mix. The size of M sand ranges from 0 to 4.75 mm while the size of P sand ranges from 0 to 2.36 mm.

Revolutionizing Construction: M Sand Solutions

Global aggregates demand is estimated to rise to 60 billion tonnes per annum by 2030 due to rising population and urbanization. Sand is produced mechanically, and the raw material for M sand mostly comes from bedrock. The rocks are crushed and ground into smaller pieces. With the availability of different types of crushers and suitable process design based on the application and the sand to be produced, it can be utilized to turn stones into just the aggregate required.

Sustainable Building with M Sand Technology

Large-scale and illegal ways of extracting natural sand can lead to significant environmental impacts such as erosion in rivers and coastlines, and changes in water’s pH levels. Thus, the use of manufactured sand can play a vital role in ensuring the sustainable use of sand. Moreover, M sand does not contain impurities like silt content, clay particles, organic compounds, or other soluble compounds that can affect its strength and durability. Although the mechanical manufacturing of sand consumes energy, its production can be carried out on-site. Thus, it helps reduce transportation costs and environmental impact.

High-Quality M Sand for Stronger Structures

Using the latest technologies in the M sand process, one can achieve better grain proportions and control in the M sand gradation with a very good particle shape and less ultra-fines generation. M sand is highly uniform in structure compared to natural sand. Besides, in concrete production, manufactured sand is less required in concrete mix by about 5 to 20% than natural sand when filling voids volume between the particles. Quality raw materials are essential for high-quality concrete. Thus, high-quality M sand will prove advantageous by enhancing the concrete quality.

Say Goodbye to River Sand with M Sand

For industrial concrete purposes, other types of sand such as desert sand are not suitable. The requirement of sand in concrete is that the grains should be adequately angular to allow them to adhere to each other, giving durability to the material. Sea sand needs to be washed first; otherwise, the presence of salt will rust the steel bar reinforce supports, making the structure brittle.

Conclusion

M sand is revolutionizing the construction industry by providing a sustainable and eco-friendly alternative to river sand. With its numerous advantages, including high strength, improved quality, durability, and cost-effectiveness, M sand is becoming the preferred choice for builders and developers. As the demand for sand continues to rise, the adoption of M sand will play a crucial role in ensuring sustainable construction practices and preserving our natural resources.